Fire in their workshop is something most people who work with wood fear. Safe use of tools, equipment and disposal of combustibles can reduce the risk to a minimum, even if the chance is always there.

Like many woodworkers, I have dozens of different containers filled with flammable solvents and finishers on my shelves.

I’ve read the warnings about how flammable some products are. Still, I never believed a fire could happen in my workshop. Turns out it did.

One day, my buddy had just finished wiping the last coat of oil on a desk he was making. Just before closing up, he threw a few of the rags he was using into a trash can.

Next day, the workshop was filled with smoke. All that was left of the trash can was a few burnt pieces of plastic. Luckily, the fire didn’t spread from the concrete floor to the wooden parts of the workshop.

I got paranoid about safety that day. So I’ve added some safety measures to my workshop to ensure the disaster never strikes and I would urge you to do the same. Listed here below is what I think anyone who works with wood, glue, paint, oils, finishes and power tools need to be safe.

Table of Contents

What to keep in your woodworking shop to prevent and stop fires

Smoke alarm

This is the most simple and cheapest safety measure you can get. I picked up a smoke alarm that also acts as a carbon monoxide detector from Amazon and mounted it on the ceiling.

This First Alert smoke detector has excellent reviews and works fine for me. It didn’t have a chance to perform yet. Knock on wood.

Fire extinguisher

I bought two fire extinguishers, just in case. I mounted one near the front entrance and the other near the rear entrance to my shop. The best extinguisher for a workshop would be “A+B+C” type that contains the dry chemical that works well with wood, electrical, and solvent fires.

I usually buy Amerex brand ABC fire extinguishers.

Metal trash can

First of all, no more plastic waste containers. Major fire threat. Invest in an industrial trash can that is made out of metal, is airtight, and closes by itself. Empty every night.

I’ve been using this Justrite can for over five years. Still works as new.

How fires start in a wood workshop

Even after I bought all these things, I was still afraid of the fire. What if there’s no one in the workshop when it breaks out? What if the source of the fire won’t be in the trash can? The fire alarm will beep, but there will be no one there to hear it and use the fire extinguisher.

The real way to prevent fires in your shop is to find a method of getting rid of or storing flammable supplies safely.

Spontaneous combustion

The fire that happened at my shop was caused by spontaneous combustion. It happens when solids in oil finishes combine with oxygen molecules to form a polymer. A byproduct of this combination is heat. At the same time, solvents evaporate. If you have a lot of oily rags clumped in a tight space with good air access, the heat will be enough to start a fire.

Oil

Any finish that has oils as its ingredient is a potential fire hazard. The problem also extends to brushes, rags, and other supplies used to spread the oil.

Lacquers

Supplies that have been soaked with synthetic varnishes and shellacs are dangerous too. Although they don’t react with oxygen, they can cause a spark of fire with electricity or can cause a chain reaction when combined with spontaneous combustion from the oily supplies.

Oxygen

Removing oxygen prevents any fire from starting. That’s why getting an air-tight trash can is so important. There are many shapes and sizes, although it can get pricey.

Even is the supplies ignite inside, the fire will be quickly put out because of lack of oxygen.

As a final safety measure, never put the trash can near any flammable objects like wooden walls, as in case of a fire inside, it can heat up on the outside and cause a chain reaction.

Heat

What about things you don’t want to throw away, and you can’t eliminate the fuel and oxygen from the equation? We can’t reduce the risk of heat generation entirely as heat is a product, not a cause. The danger of fire arises mainly if it’s allowed to build up in a tight space.

Practical prevention to stop fires in your workshop

There are several ways you can prevent your materials from going up in flames.

Cool and clean your material

After you’re finished with it, put it in water. This will both partially dissolve and clean your equipment from oil/lacquer and prevent fire in case of heat buildup. It doesn’t solve the problem entirely, but materials that will not be damaged by water can be stored like this even overnight. The downside is this creates contaminated water which should be disposed of properly.

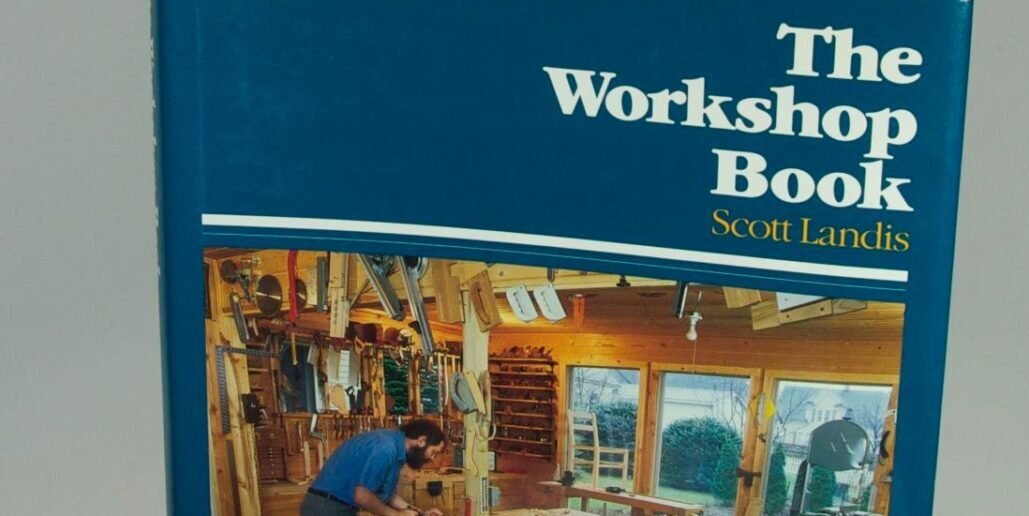

Keep fire equipment accessible

Never keep your woodworking supplies, particularly the bulky tools, in front of the fire extinguishers. You should be able to react quickly in an emergency so all emergency supplies must be accessible. Keeping your workshop clean and tidy is really a simple way to prevent fires.

Burning the material

Another option is burning your rags in a controlled environment. If it’s allowed by your local laws, you can burn your old, oily rags. However, this is not very environmentally friendly.

Spread out your rags

My favorite trick. Just spread out your rags on concrete. Rags have the highest chance of combustion if they are packed together. This allows the combustible solvent to evaporate safely.

Clean up sawdust

Due to its great flammability, sawdust significantly increases the danger of fires and explosions when an ignition source is present. Large amounts of fuel, combustible materials, and ignition sources such electrical wiring, electrical motors, sparking equipment, cutting, and welding processes are common in workshops. A buildup of wood dust may explode under pressure or catch fire if exposed to open flames, impact sparks, or broken electrical equipment. Never use compressed air to blow collected dust when there are ignition sources nearby. You may lessen the risk of sawdust fires by regularly cleaning equipment to reduce sawdust collection and by positioning electric panels and transformers as far away from dust-producing gear as is practical. Ensure your workshop has enough ventilation, and keep the collection of wood dust to a minimum by regularly cleaning the shelves, ceiling, walls, and floors. The exhaust ventilation system has to be inspected and cleaned as well. Exhaust ventilation is the primary engineering control for sawdust, and proper housekeeping is crucial. For more info what can be done with sawdust read: What to do with sawdust?.

How to get rid of your flammable materials

Dry waste

Simple. If the materials are completely dry, they are safe to throw away. If you hang up a paintbrush and it’s dripping, it’s not yet safe to being thrown away.

Liquid waste

Disposing of liquid waste is more complicated. Never pour them down the drain or into the ground as they are major pollutants and can contaminate drinking water.

If you want to put liquid waste like a can of lacquer in a communal trash can, the best way is to combine it with kitty litter that can absorb the liquid until it’s perfectly solid. Set it outside after the vapors have evaporated completely. Only then you can dispose of it safely with the rest of your trash.